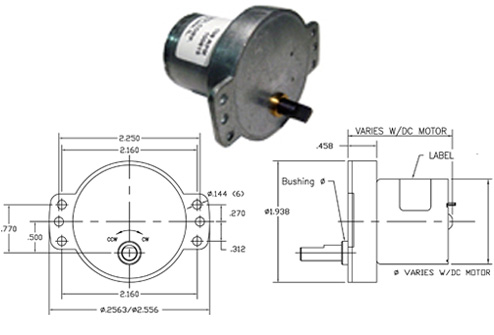

DC Motor – Model 225

The 225 motor is a permanent magnet gear motor utilizing a standard round gear box die cast housing. It can be supplied with an array of DC motors. The specific DC will be tailored to meet the customer’s application requirements. Typically, a three bar commutator and a choice of carbon brushes or bifurcated silver alloy brushes provide long life, quiet operation and low starting voltage. The three slot rotor is supported by permanently lubricated sintered bronze bearings. Available in a wide range of speeds and an excellent choice for applications requiring reliability and quiet operation at a low cost.

DC Gear Motor – Model 225 Features

- Designed for reliability and quiet operation

- Rugged die cast gear housing

- Output shaft may extend from front, rear, or both ends and is supported by bronze sleeve bearings

- Mounting is compatible with other pear-shaped motors

- Integral RFI filtering can be furnished

- Totally enclosed for protection against contaminants

- Options available…consult factory

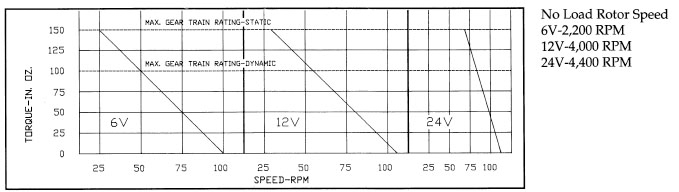

Specifications

Rated Torque

Curves below typify rated torque outputs for standard 6, 12, and 24 volt motors. Values may vary ±15% and are to be used only as a guide to determine available performance. Exact torque speed curves can be supplied once the optimum DC motor is chosen.

Voltage

| Rated Voltage | Operating Voltage |

|---|---|

| 6 VDC | 3-8 volts |

| 12 VDC | 9-18 volts |

| 24 VDC | 19-30 volts |

Current Draw

| Voltage | Rated Load | No Load |

|---|---|---|

| 6 VDC | 70mA | 16mA |

| 12 VDC | 60mA | 30mA |

| 24 VDC | 35mA | 15mA |

Current draw may be higher in certain units depending on the type and amount of lubrication used in the gear trains.

Ambient Operating Temp. Range

-20°C to +60°C

Lubrication

Permanently lubricated. Special lubricants available for operation under -20°C…consult factory (-40°C min.)

Direction of Rotation

DC Motors may be operated in either direction depending on polarity as applied to the terminals. Direction of rotation of the output shaft with respect to polarity markings of the terminals will depend upon the number of gear reductions used in the gear train. Instantaneous reversing is not recommended in order to provide maximum brush life. Bi-directional DC Motors available.

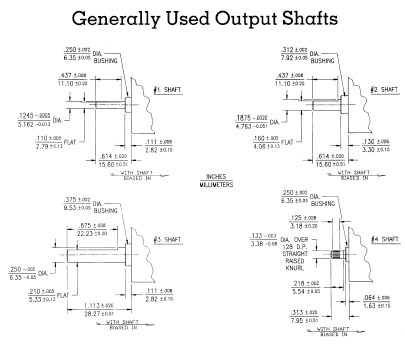

Output Shaft Options Available

Dielectric and Insulation Resistance

Dielectric: 1000 volts RMS for one minute between terminals and case.

Insulation Resistance: 10 megohm minimum measured with 500 VDC applied.

R.F.I.

The 225 motor is available with an integrally assembled radio frequency filter to suppress RF noise and enhance brush life.